GSES Backhoe 101

WELCOME TO:

G.S.E.S. BACKHOE 101

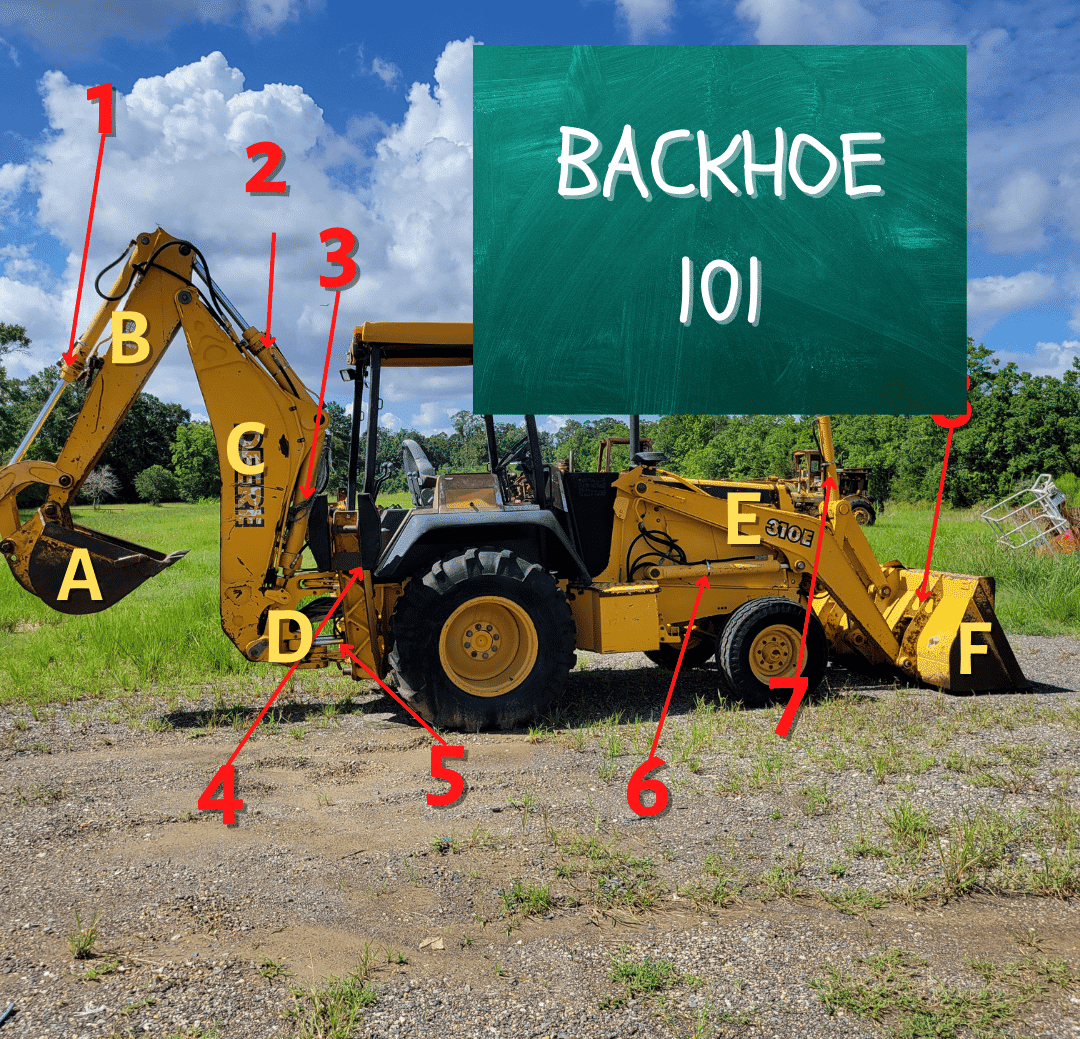

Backhoe Cylinders and Working Equipment

Backhoe Hydraulic Cylinders:

There are many names for each cylinder on a backhoe, but we’re going to give you the terms that we use, so there is no confusion when you are researching or buying parts. Each cylinder is named for the part that it manipulates. This is important to note, because the Dipper Cylinder sits upon the Boom and the Bucket Cylinder sits on the Dipper, so it can get confusing when we’re not on the same page, and mistakes cost time and money.

- Backhoe Bucket Cylinder (Sometimes Called the Bucket Curl Cylinder) Manipulates the Backhoe Bucket (A). Even though the majority of the cylinder is pinned to the dipper, it is named for the bucket that curls toward the machine when the ram is extended.

- Dipper Cylinder (Also Arm or Stick Cylinder) Manipulates the Dipper Stick (B) Again, most of the cylinder rides along the Boom, but the rod end is pinned to the Dipper and manipulates it.

- Boom Cylinder. Manipulates the main boom (C)

- Stabilizer Cylinder (Also Outrigger Cylinder). Manipulates the Stabilizer or Outrigger Arm. Side-Specific on some makes.

- Swing Cylinders. Manipulates the Swing Tower, or Swing Frame (D) Side-Specific on some makes.

- Loader Lift Cylinders. Raise and lower the Loader Frame (E). Side-Specific on a few makes.

- Loader Tilt Cylinder (or Loader Bucket Cylinder). Case and Ford usually have one on each side. Cat, Komatsu, and most Deere models just have one in the center. Models with two cylinders are often side-specific.

- Clam-shell (or 4-in-1 Bucket) Cylinder. *Not Pictured* Some backhoes have a loader bucket that opens and closes. If this model was equipped with a “4-in-1 Loader Bucket” the cylinders would be pinned to the back of the Loader Bucket (F)

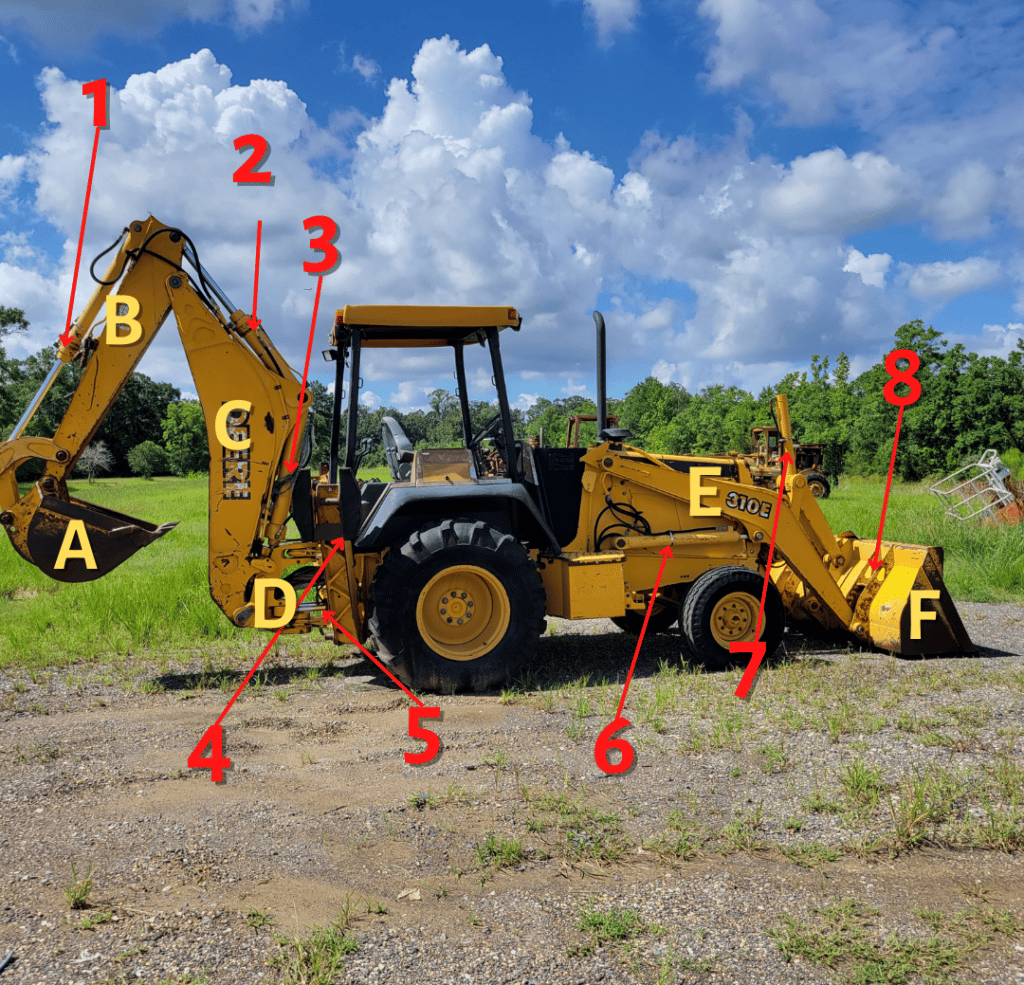

Backhoe Working Parts

The “Working Parts” on a Backhoe Consist of the Buckets, Arms and the Frames that They are Attached to.

I Want to be Clear About this Section, Because if Our Terminology is Mixed up on these Working Parts Mistakes Cost Even More Money and Time, Because all of these Parts Ship VIA Freight!

A. Backhoe Bucket: Pretty Self Explanatory. It Pins up to the Backhoe Links and Dipper Arm (B).

B. Dipper (Sometimes Called the Arm. NOT a Boom) Pins Up to the Backhoe Links, Bucket (A), and Boom (C).

C. Boom (NOT an “Arm, Stick, or Dipper) Pins to the Dipper (B) on one end and the Swing Frame (D) on the Other.

D. Swing Frame (Also Swing Tower). Pins to the Main Frame of the Machine. The Boom (C) is Pinned to it, and the Swing Cylinders (5) Move the Swing Frame Left and Right.

E. Loader Lift Frame (or Lift Arms). Pin to the Main Frame of the Machine, and the Loader Bucket (F)

F. Loader Bucket. Again, this one is Easy. It Pins to the Loader Lift Frame (E)